Sophisticated Multi Tasking machines of today employ numerous operations to achieve high productivity at desired quality levels. These systems in turn employ special and specific oil with a wide viscosity range. These oils stores heat during its operation and the continous addition of heat reduces the viscosity of these oils. As the oil thins down, the system stores to malfunction due to internal leaks. Therfore, it become essential to maintain specified temperature limits for this oil during operation A oil chiller is normally connected in parallel to oil tank thorough a dedicated built in oil pump. AWE Industrial Cooling System is a leading oil chiller manufacturers which holds years of expertise. If you are searching for oil chiller manufacturers, then please contact AWE Industrial Cooling System now!!

AWE Industrial Cooling System Manufactur

AWE Industrial Cooling System Manufactur

About AWE Industrial Cooling System

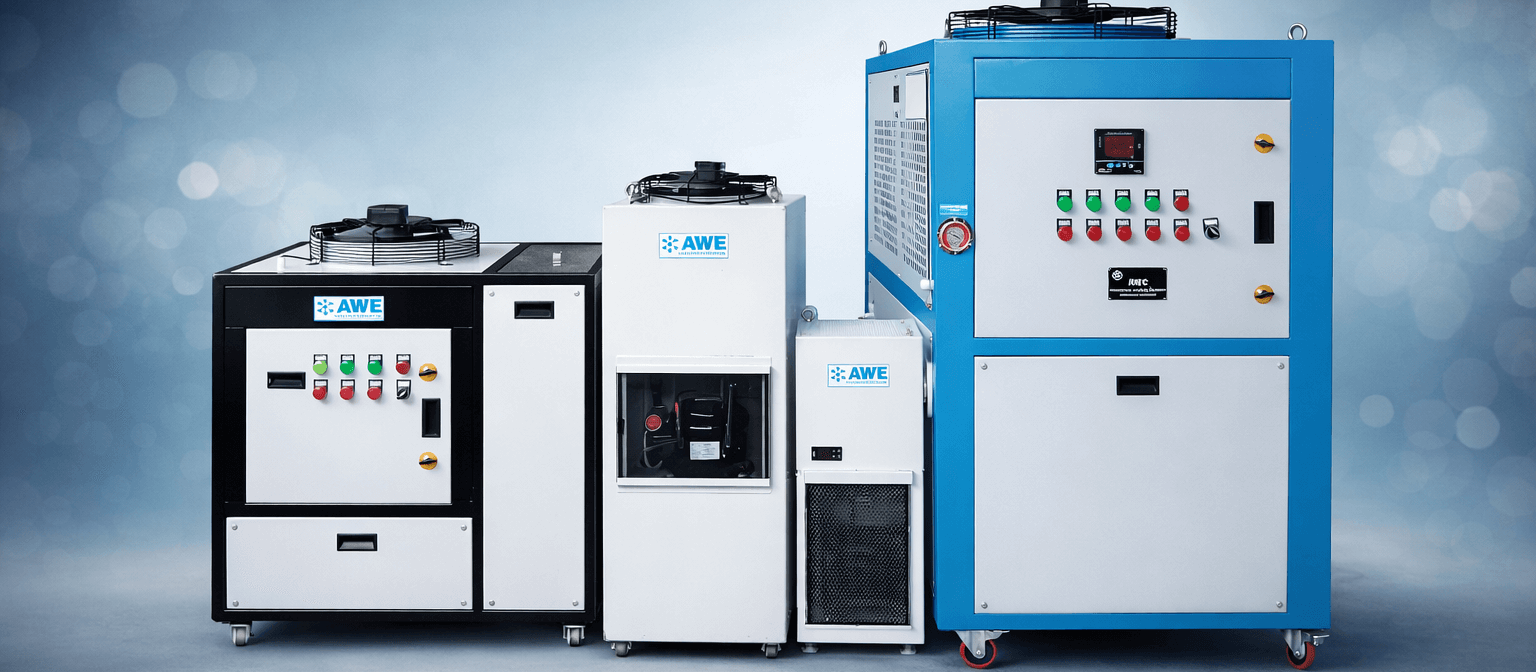

The Best Industrial Chiller Manufacturers in bengaluru

Products

Featured ProductsWhat We Do

Have any custom requirements?

Latest Updates

Read Our Latest Updates & News

Testimonials

RN Systems

They provide Excellent Service and on time delivery of chillers, and panel coolers

Agastya

They provide Excellent Service and on time delivery of chillers, and panel coolers

×

![]()